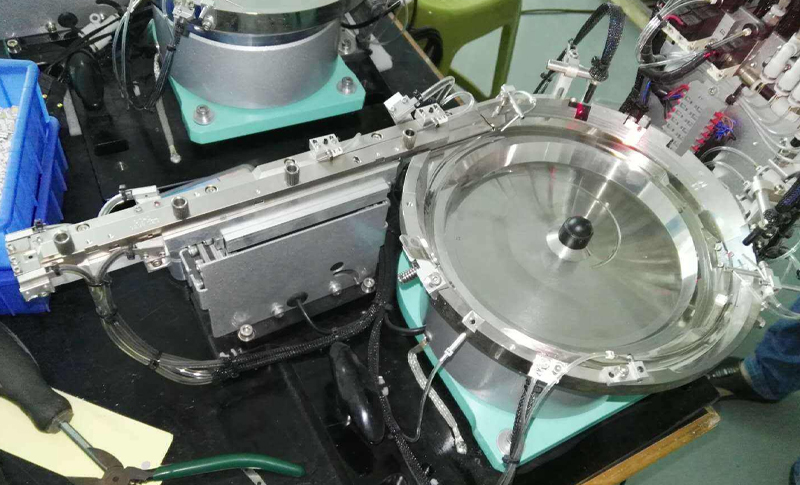

The three-in-one vibrating plate rack part adopts the hydraulic expansion method, and the arc-shaped tile plate is driven by the wedge-shaped slider structure, with low resistance, low wear, low failure rate and long service life.

The operation of each auxiliary device of the three-in-one vibrating plate is based on oil pressure, air pressure or electricity as the power source. The coiling machine adopts cantilever pressing, motor drive control, forward and reverse rotation, and hydraulic cylinder to hold the iron ring, which is easy to operate, easy to maintain and has a low failure rate.

The main shaft of the three-in-one vibrating plate rack adopts the hydraulic expansion system, which has a large tightening force and good safety. Equipped with hydraulic power pressing arm, and equipped with one-way clutch device, the material is pressed without being scattered, and the material can be prevented from rebounding. The material rack is automatically operated by contrast photoelectric control. Equipped with automatic feeding device, automatic pulling device and pressing device. The feeding device is divided into a feeding pressing arm and a feeding feeding arm, and the sensor controls the distance between the two parts. The material rack has an automatic braking function to prevent the material from breaking the motor base by inertia, and has a release limit function of the material rack to prevent the oil cylinder from being damaged.

The three-in-one servo vibrating plate combines the functions of the reel rack, the feeding trolley, the straightening machine, and the vibrating plate, which greatly reduces the area occupied by the previous feeding device, and can work with the punching machine at the same time. The reel mounted on the reel rack is controlled by the sensor below the reel, and the NC vibrating plate can be used to level the material while simultaneously feeding the pre-set length of material into the punch die.

The three-in-one vibrating plate can improve production efficiency, which is hundreds of times that of manual stamping and (shearing), and the finished product of feeding stamping and (shearing) has high precision, saving factory manufacturing costs and saving human resources.