As we all know, the three-in-one vibrating plate is an automatic machine specially designed for conveying materials, and it is also an indispensable equipment in the light industry and heavy industry. The machine tool adopts pneumatic clamps connected with dovetail grooves to clamp the steel plate. The clamps are easy to move, which reduces the bending deformation of the material and reduces the processing dead zone. The servo motor with high torque and high precision, the driver with long life and high precision, and the precision ball wire are selected. Bars and high-performance linear rolling guides can meet various requirements of the stamping process, and are especially suitable for products with relatively high machining accuracy requirements, which overcomes the use of defects such as large punch vibration, unstable accuracy, and short die life.

There are many types of vibrating discs, the editor summarizes several, as follows:

1. Buried scraper vibrating plate

The buried scraper vibrating plate is composed of a closed shell, scraper chain, driving device and tension device. When the buried scraper vibrating plate is working, the material enters the bearing section of the casing through the feeding port, and is pushed by the scraper, and moves forward together with the scraper chain as a whole. The empty section of the enclosure returns. Because the scraper chain is buried in the material and moves forward together with the material during work, it is called "buried scraper vibration plate"

2. Belt vibrating plate

The general structure of the belt vibrating disc is mainly composed of conveyor belt, roller, supporting device, driving device, tensioning device, unloading device, cleaning device and frame and other components. The belt vibrating disc is a continuous vibrating disc machine. It uses a conveyor belt around the front and rear rollers as a traction and bearing member. The driving rollers rely on friction to drive the conveyor belt to move and drive the materials to run together. To achieve the purpose of conveying materials.

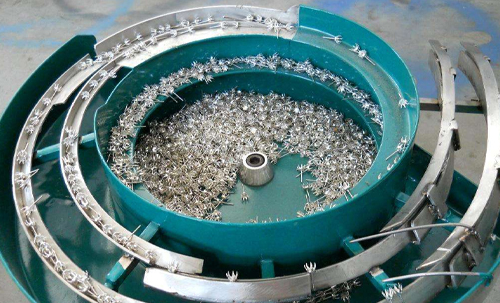

3. Spiral vibration plate

The spiral vibrating plate is mainly composed of a trough, a spiral body composed of a spiral blade and a rotating shaft, bearings at both ends, an intermediate suspension bearing and a driving device. When the screw rotates, the material entering the machine groove is subjected to the normal thrust of the rotating blade. The radial component of the thrust and the friction force of the blade to the material will make the material rotate around the axis; and the gravity of the material and the friction force of the machine groove to the material It also prevents the material from rotating around the axis. When the axial component of the normal thrust of the helical blade to the material overcomes the friction force of the machine groove on the material and the radial component of the normal thrust, the material rotates together with the spiral, and only moves forward and far along the material trough.

The above are the principles and types shared by the vibrating plate factory with friends, all of which can be widely used in the cold bending forming production line of shelves, and can achieve high position control accuracy; and the online pre-punching mode and hydraulic shearing mode can be independent For example, there is no online pre-punching mode in the production process of shelf beams.