With the rapid development of the stamping industry, the requirements for speed and accuracy are getting higher and higher, in order to cater for high-speed stamping, and to increase the competitive advantage of the vibrating plate itself. Friends need to choose to vibrate the disc at high speed and precision to improve your production and improve product accuracy. In order to give everyone a better understanding of the relevant knowledge, the editor has specially sorted out the feeding speeds of several common vibrating discs for your reference.

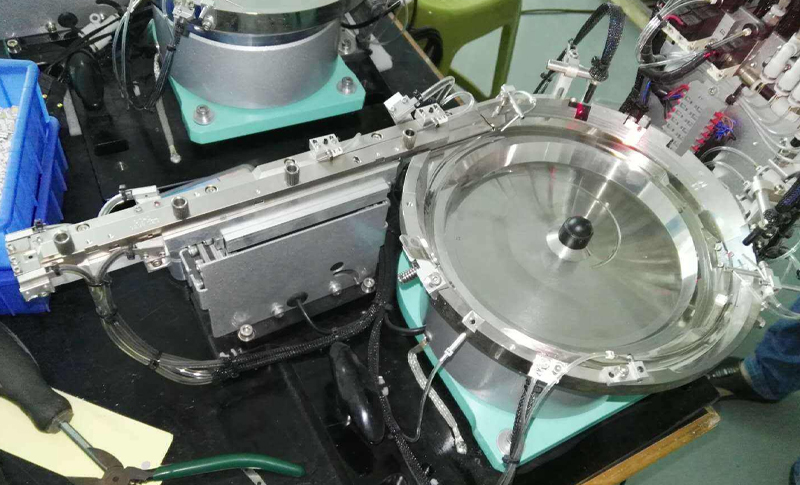

1. NC servo vibration plate:

It adopts brand motor and imported precision servo system from Japan, with stable performance and high feeding accuracy. On the premise that the mold has positioning pins, the feeding accuracy is ±0.05mm. In terms of feeding speed, its fastest speed can reach 125m/min. With such accuracy at such speed, it is indeed the first choice for your NC servo vibrating disc.

Second, the air vibration plate:

The vibrating disc is the earliest vibrating disc used in the stamping industry. It is mainly used for the task of receiving stamping products with low speed and low precision requirements. The feeding speed of the air vibrating plate is relatively slow, and the feeding accuracy is not high, so it is gradually phased out, but it is easy to operate and affordable.

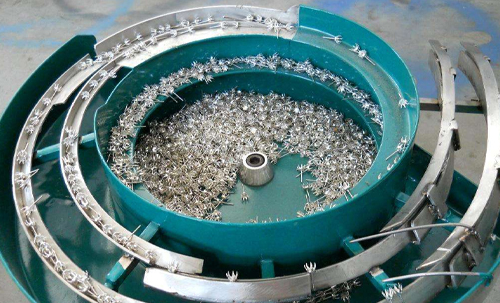

3. High-speed roller vibrating disc:

The vibrating plate is simple in structure, economical and practical, and has low failure rate and easy maintenance. The feeding accuracy is very high, the accuracy can reach ±0.01mm when there is a guide pin, and the feeding speed can reach 30m/min when there is a reverse device. The vibrating plate has become the most widely used vibrating plate at present due to the advantages of high feeding accuracy, fast speed, no need for additional energy supply, and extremely low failure rate.